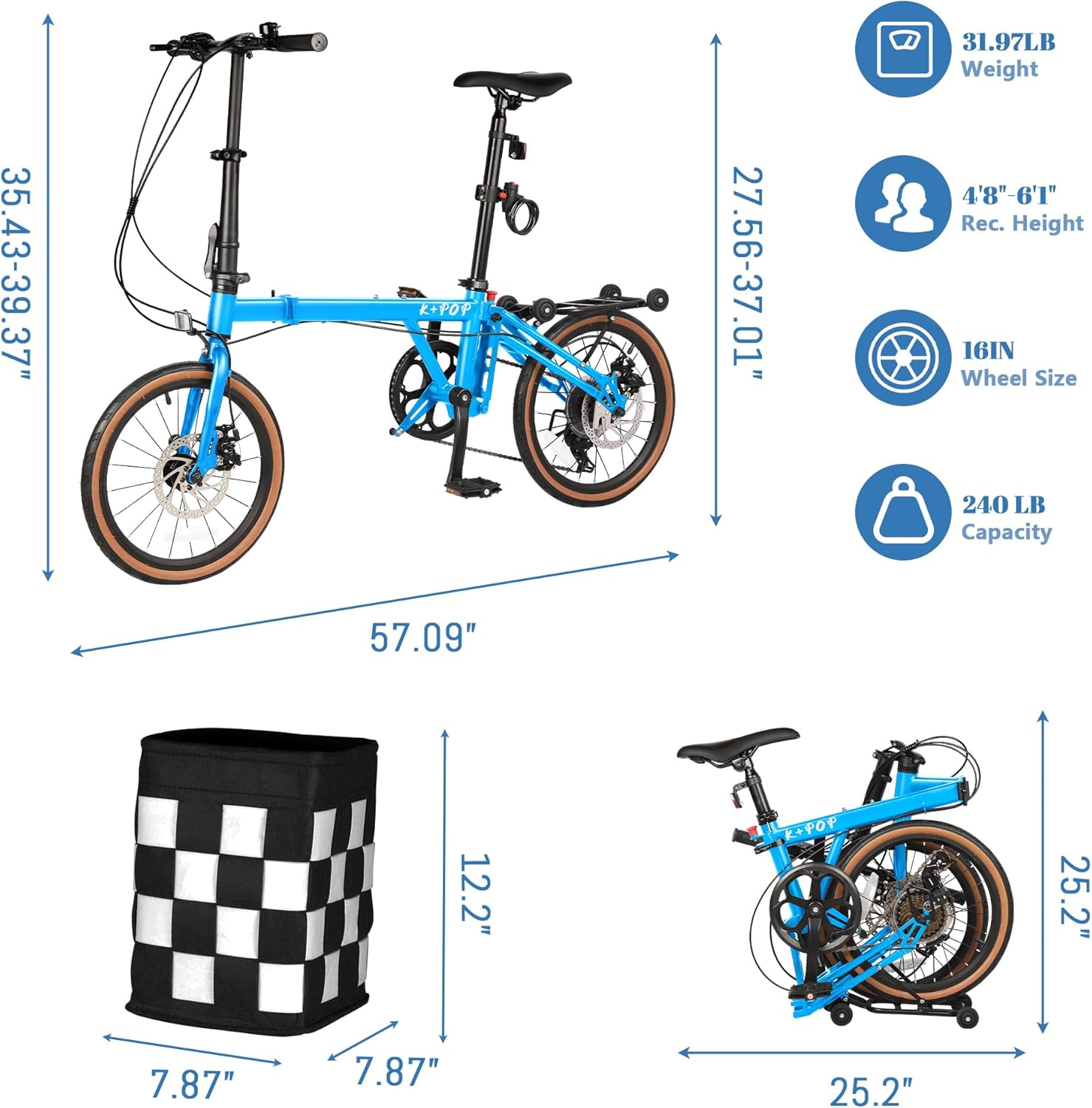

The K+POP trifold is derivative of a Brompton, but not actually a Brompton clone. At only ~$200 it is a downmarket model that has a less optimized fold and some cost savings, but is surprisingly functional. It’s made mostly from steel and the 32lb quoted weight is accurate. As far as I know, this is one of the first trifolds that isn’t a close Brompton clone, so I assume the innovations are in fact, innovative, although that could be inaccurate.

The frame is less optimized than the Brompton, lacking the curved main tube. When folded, it wasn’t actually much shorter than a 16″ bifold, but it would likely be if it were more vertical with the rear rack removed. Unlike the Brompton, there is no rear suspension, just a safety pin and a QR skewer. The safety pin does not have to be pulled to unfold the bike, and it strong enough to lift the bike when folding it, making it relatively quick and painless and slightly easier than the Brompton latch. The QR skewer did need to be unscrewed a few turns each time however, making the fold here a bit slower. It does have bottle cage bosses on top of the main tube though, which is nice.

The rear “triangle” lacks chainstays. This wouldn’t be useful for a belt drive due to chainstay length effectively shortening while folded. While on a bifold bike it would be less of an issue, it seems questionable on a trifold bike. However, this modification to the design is not for looks, but rather a way to cut costs and make it compatible with a standard derailer. No chainstay makes it easier to design the fold since chainstay clearance is no longer a concern. It also allows the chain hanger to pick up the chain when folded, but be out of the way when unfolded, as opposed to the Brompton’s chain tensioner, or special derailers requiring special chain tensioners. That being said, the rear end is reasonably stiff for this kind of bike, I’ve ridden folders that were stiffer, and vintage folders that were flexier.

The version I received uses an auxiliary dropout and a spool that drops in as opposed to the Brompton’s fork hook, and the K+POP design seems more durable, less obtrusive, and none of the moving parts touches the paint. There is however, no handlebar catch, so without being strapped down, it could flop around.

The stem uses a tooless lever with a safety catch, making this operation easier than the Brompton. It is also QR height adjustable, clearly marked for height in cm, and has an anti-rotation groove. The stem also has a QR handlebar clamp, but this is not terribly useful on flat bars unless you need every inch of space. Functionally, it seems superior in most ways other than optimizing fold size. The lower tube is made from steel and the inside tube is made from aluminum, and it attached using a 25.4mm quill (for 1-1/8 threaded steerers).

The seatpost locks the frame like a modern Brompton, making it easy to lift. It’s a simple steel seatpost with “guts” as a saddle rail clamp, but it seems to function. Weight could probably be reduced for swapping it, but it’s unlikely you can make it as light as a Brompton.

The wheels on the rack roll smoothly and are functional. My rack was not the full tubular version, but still felt stiff when all the bolts were tightened. The rear rollers were prone to bending, but using a threaded rod that passed though both as an axle increased the strength. With the front roller extended, it felt reasonably stable and rolled easily.

The shifting is handled by a sub-Tourney non-slant Shimano unit, but it shifts the basic 7 speed freewheel fine. The derailer hanger is integral to the frame and straight, unlike more finicky claw hanger models. It also has a derailer guard, which adds to the folded size, but useful to prevent the hanger from getting tweaked. It’s very functional, I was going to swap out the derailer, but realized I don’t need to until this one wears down.

The headset is a difficult to adjust threaded headset, which requires a large pin wrench and faith in the toothed washer to adjust. The bearings are in a retainer ring, making it easy to grease. There was some grease, but it could use more. Mine also required adjustment out of the box.

The breaks are surprisingly powerful, likely due to the small wheelsize and mechanical advantage offered. This has nothing to do with the quality of the brake, as they are basic mechanical calipers that would be scorned on any full size bike. This was another part I had an upgrade replacement ready on hand, but I think the brakes may actually be too powerful, so I might swap the brake levers to Vs.

The cranks are basic square taper cranks with a swaged steel chainring. The guard helps a little on a commuter bike, and a full chainguard (hockey stick) or chaincase wouldn’t really work on a trifold. The bottom bracket is surprisingly a cartridge unit, which is nice and requires no maintenance or adjustment.

The hubs also had big rubber seal cartridge bearings and required no adjustment, a pleasant surprise on a bike at this price point. The axle nuts were done extremely tight, and the caps has to be pried off with a small flathead, something to keep in mind for flat changes. It also required a brake adjustment after reseating the wheels. The front needs the tabbed washers as the dropouts point down rather than forward, and the disc brakes could eject the wheel. The front should be done up very tight. The tires are some kind of Innova skinwall, with maybe a 30 TPI casing. They rolled decently well, much better than tires with thick rubber sidewalls. There is no clearance for larger tires or fenders. Annoyingly, the front came laced radially, which is not appropriate for disc brakes, and I have to determine if it is worth it to relace the wheel.

All in all, it’s a surprisingly nice little folder for the price point, and seems like it would make a great beater/commuter. It’s actually fine and doesn’t feel like complete junk, but it’s obviously not a Brompton. My biggest gripe is the radially laced front wheel, and relacing the wheel is a major job for those not experienced.

Mods:

Relaced front wheel to semi-radial/2x. I used 10x 157mm spokes on the disc side, 155-157mm is probably fine. Cost me about $7 online and it wasn’t worth the effort of cutting and threading spokes at the shop. This noticeably reduced torsional flex of the rotor, and brake juddering. This thing can easily do stoppies.

Roller wheel axle. Used a 1/4″ threaded rod and some nuts to make a solid rear axle for the rack mounted wheels so the tabs they are mounted to don’t bend. Maybe $3 worth of hardware I already had.

Cut the seatpost. The bottom of the seatpost has a taper and a second 7/8″ neck, since the long seatpost is basically just 2 seatposts back-to-back. The taper serves a purpose to guide the seatpost into the frame lock, but the 7/8″ neck does nothing, it doesn’t allow the seatpost to go any higher, but cutting it off will let the seatpost go lower when folded. Free.

Aluminum handlebar. The original handlebar is steel, and aluminum makes it marginally lighter. From the parts bin.

Bottle cage. Unlike other folders, this one has a bottle cage mount. Nice.

Conventional 1 1/8″ headset locknut and keyed washer. The stock one prevents easy adjustments and there was an issue where moving the stem back and forth would also shift the stock locknut and cone because of the contact over the large radius.

Freehub hub. This takes a lot of work, and 135mm rear on a folder is usually seen as a disadvantage due to excessive width, but the standard width lets me put a standard hub in, which lets me get more and higher gears. Might as well take advantage of the full size OLD to run extra gears. I think bikes like Mint have reduced OLD and have a standard 8-10s freehub. Hub was about $40 plus the time to rebuild the wheel.

11-speed gearing. The stock freewheel is 14-28 (not even 13-28), so an 11-28 cassette gives 3 more gears on the top end, which is appreciated. Even 13-28 is an improvement due to the small 16″ wheels. The frame doesn’t have much room for the chain run of a larger chainring, so this is the way to get higher and more gears. the 48T chainring on 16″ is about equal to a 30T chainring on 700c. Double not cheap. I made mine work with an XT shifter (Dynasys), but the Micronew 11 speed shifter works with old Shimano cable pull so it is easy to find an old decent short cage derailer. I would have gone 12, but I had some 11 stuff lying around since the MTB got upgraded from 11 to 12, and I didn’t really need 12, since it’s mostly for the top end.

Cranks. The original cranks are swaged and the Q-factor is kind of high, had some lying around.

Folding pedals. Really only needed on the right side, but Brompton pedals have a left-only folding pedal, so I had to buy a pair. About $20.

If you’re buying the bike with the intention to upgrade, you might just look at a Mint ($500+) though. I got this bike for cheap, and had a lot of parts already.