I sold my oxy-acetelyne torch to buy an oxycon-propane setup that’s popular among glass blowers, jewelers, and now among frame builders. An oxyhydrogen setup would actually be ideal for convenience as it would just use water for fuel, but hydrogen has its own issues like low BTU, hydrogen embrittlement, flame visibility, high power requirements, running premix in hoses, etc. That being said, there are commercial HHO brazing gas generators.

This is a summary of technical considerations for the purposes of equipment selection, and at this point in time not a guide on how to use or set up an oxycon-propane system. I don’t have experience with all of this equipment. Like most other things on this site, these are my personal notes so I don’t forget things.

Table of Contents

- Oxygen Concentrator

- Propane Accessories

- Other

Oxygen Concentrator

An oxygen generator/concentrator is a medical device that filters oxygen from the air to produce ~90% pure oxygen. These are very expensive when new, and very cheap when used because they must be professionally refurbished to be resold for medical purposes. There are numerous brands, but any real RX medical device concentrator can be assumed to be of good quality as they are highly regulated. For the compact consumer grade ones with flashy LCD screens on Amazon, caveat emptor.

Output capacity – Usually either 5 lpm (10.6 scfh) or 10 lpm (21.2 scfh). Oxygen purity tends to drop as flow increases. 10 lpm models tend to have much higher pressure. Some models like the Devilbiss 525 are reported to tolerate higher flow than listed, while other brands are very sensitive to excessive flow beyond 5lpm. 5lpm is adequate for framebuilding, but frame building is about the limit of a 5lpm concentrator.

Pressure – Usually 5 psi for a 5 lpm model. This is very low for an injector torch (Harris’ injector mixer among the models listed here), but usable for equal pressure mixers (most mixers). Some recommend forgoing a flashback arrestor to avoid pressure drop. I do not recommend this. I found with a high flow (regulator) flashback arrestor there was only a 0.5-1psi measured pressure drop on both my 5L (7 psi) and 10L (20 psi) machines under various conditions, although this may vary from arrestor to arrestor, even of the same make. At 7 psi it was still able to deliver over 4 lpm with a small 0.9mm single orifice tip (XXS TEN-0 equivalent) with equal pressure mixer. Some models like the Devilbiss have higher pressure at 8.5 psi. 10 lpm models will often have much higher pressures around 20 psi. Oxygen concentrators have internal pressure regulators that can be adjusted, and manuals will list a range of allowable pressures. These regulators aren’t great, but because there is no gradual pressure drop from tank pressure, they work okay and an external regulator is not required. They also all have flow meters and flow valves. For a 20psi oxycon these aren’t really a substitute for an external regulator though.

Noise – Oxygen concentrators make noise because they have air compressors, spec sheets will usually give a db figure. It doesn’t really matter, but something to note because some are noticeably louder than others.

Hours – All oxygen concetrators have an hour counter on them. They are meant to be able to be used 24/7 for years, so a unit with a few thousand hours on it will last many years to come as an oxygen supply for a torch.

Fittings – Some come with a threaded fitting which matches a “B” type oxygen fitting, identical to those on torch hoses. Some use a barb fitting. Most of these should have a cannula adapter which has a plastic barb to “B” type adapter. It’s possible to make a barb to “B” adapter with brass fittings if the plastic one isn’t trusted. Ones with “B” fittings will come with a “B” to barb adapter. While more people prefer the metal B fitting, one advantage of making a brass adapter is you can use a NPT T fitting which also lets you put a pressure gauge or relief valve on the output.

Humidifier shelf – All oxygen concentrators have a place to put a cup filled with water used as a humidifier for the oxygen. This only matters if you want to be able to put a 1lb propane canister on it so you have a portable oxy-propane setup. Designs like the Devilbiss don’t really facilitate this. Most others do. This is completely irrelevant if you will use a 20lb BBQ tank.

Portable/pulse – Do NOT buy a battery powered portable pulse type, they do not put out steady oxygen and only produce oxygen as needed with breathing. This is the wrong type.

Home fill – These systems let you full up a portable reusable oxygen tank meaning you aren’t limited by the machine’s pressure or output or size.

Below is a comparison of 3 common oxygen concentrators in my area. What is common in your area will largely depend on the distribution network where you live. There are many other variants which may be available, but these are the common ones here. I have personal experience with 2 of them.

| Phillips Everflo | Devilbiss 525DS | Devilbiss 1025DS | |

| Output Volume | 5 LPM (10.6 CFM) | 5 LPM (10.6 CFM) | 10 LPM (21.2 CFM) |

| Output Pressure | 5-7 PSIG | 8-9 PSIG | 19-21 PSIG (8.5 aux) |

| O2 Purity @ 5LPM | 90-96% | 87-96% | 87-96% |

| O2 Purity @ 10LPM | – | – | 87-92% |

| Fitting | 3/16″ barb | 9/16-18 “B” | 9/16-18 “B” |

| Size (LxWxH) | 9.5″x15″x23″ | 12”x13.5”x24.5” | 12”x13.5”x24.5” |

| Weight | 31 lbs | 36 lb | 42 lb |

| Noise | 45 db | 54.5 db | 69 db |

| 1lb Tank Shelf | Yes | No | No |

| Notes | The alarm is much more annoying and goes off if you try to go above 5 LPM due to “high flow” not low purity | Same size as 525, but heavier and with more compressor noise |

The EverFlo makes a good welding cart style and should still be able to run normal size framebuilding tips. It has a shelf for a 1lb propane tank, it has a smaller footprint, the top has a lot more nearly flat area to attach storage (you can easily attach a bin to hold your torch, tips, soapy water spray bottle, flux etc.). However, the alarm is very annoying and trying to get more than 5 LPM of flow will set off the audible high flow alarm. Otherwise it is fairly quiet, and the most noticeable noise is the solenoid valves hissing. If you plan on doing jewelry, the smaller one is better. The bottle shelf isn’t perfect, but but in a better location than most since it is in the rear and gives you access to the regulator key without it sticking out and it has plenty of clearance for gauges. It’s plenty adequate for the hobbyist when it’s going to spend more time being stored than used, and very easy to wheel everything out when you need it.

The 1025DS makes a good shop oxygen concentrator to be paired with a BBQ tank and tool/welding cart to hold your stuff that is stored where you’re going to use it. The compressor is much louder (db are not linear, every 10 db is about twice the perceived volume), although not unbearably loud, and propane flames are pretty loud when the torch is actually on. It has high enough pressure that pressure drop from a flashback arrestor should not be a concern. I feel the pressure is actually a bit high and could use a regulator, although pressure can be adjusted with the flow valve and there’s an aux port with 8.5 psig. The male B fitting makes it easier to attach a torch hose, but actually makes it harder to add in an external regulator or pressure gauge. You can kind of reroute the “B” fitting to just use a hose and stick a 1lb bottle 3/4 of the way on the shelf, but you’d have to fabricate a shelf and a way to strap the bottle in, as well as remove the “B” fitting and route with just a hose. Even then the regulator key sticks way out. There’s also just no place to mount stuff. It’s considerably worse at being a moveable brazing cart. It’s undoubtedly a more capable machine, but it’s also hard to say there are any advantages if you don’t plan on running an injector mixer or big tips.

I use the EverFlo 5L because of space concerns. It is plenty adequate, and you don’t really have to feel like you’re missing out by not buying a 10L. The use cases for 10L are somewhat niche. 10L ones are rarer and more expensive, so I would not pass up a 5L to wait for a deal on a 10L to pop up. If a 10L is readily available for a good price, you may want to buy it just to keep future options open. If you use 1/8″ brazing hose, it really doesn’t tolerate high flow well either.

Cheap option: Whatever 5L medical generator you can find on craigslist for $200 or under

Expensive option: Whatever 10L medical generator you can find

Propane Accessories

Propane sometimes requires different and dedicated equipment that is not the same as acetylene.

Regulator

First thing is a regulator, which keeps the pressure relatively constant. I feel this is a part that’s important to spend a lot of money on. Fuel leaks are very bad. Regulators are going to be the only propane accessory that has moving parts that move on their own. Cheap ones have been known to malfunction and not regulate properly, sometimes resulting in ever increasing gas pressure and flow. Not to be excessively patriotic/jingoistic, but buy a nice MUSA one. You could in theory run a 1/2 psi BBQ one with injection mixer, but I won’t recommend it. There are increased risks with a regulator malfunction once you add pressurized oxygen into the mix. Propane is stored as a liquid, and tank pressure will vary mostly based on temperature (environmental temperature, and temperature drops from decompression), so single stage is fine for 95% of the propane in the tank. Contrary to popular belief, output pressure rises as tank pressure falls.

Fittings – The fittings will define physical compatibility with the rest of your equipment. BBQ tanks use CGA-510 threads, also common for acetylene. 540 fittings will not work. A “steak saver” can adapt CGA-510 for use with 1 lb camper stove propane bottles. Most regulators bodies have NPT fittings and gauge and are highly modular, so input, output, and gauges can be swapped out as needed, but NPT fittings should only be swapped as little as possible due to wear and deformation of threads. Most will have “B” (9/16″) output hose fittings and need adapters for A hoses. Smaller HVAC port-a-torch regulators may have “A” hose fittings, but are usually for portable acetylene tanks.

Single/dual Stage – Dual stage regulates better. Dual stage costs a lot more. It’s just two regulators in series. You may have to adjust your flame every now and then with a single stage. Propane is stored as a liquid, so pressure is pretty steady and based on vapor pressure rather than the ideal gas law and mass of fuel remaining in a static volume tank.

Gauges – BBQ regulators often have no gauge. A decent regulator will have real gauges with pressure markings. For frame building a 15(30) psi low-pressure/output gauge is better, but propane regulators tend to come with ~60 psi gauges. 15 psi gauges are 30 psi gauges but with half the range. 15 psi models may have different springs to regulate lower pressures better, but my gut feeling is a lot of the time they don’t. Nice regulators will have 2 gauges, the other one is high-pressure/input. It doesn’t tell you a lot because propane is liquefied so unlike acetylene, you can’t tell how full your tank is from the pressure until you’re running on fumes (~last 5%). I still prefer it because it can be used for some leakage diagnostics and tells you when you’ve cracked open the fuel valve on the tank, or drained any remaining propane past the tank valve.

Acetylene – According to parts diagrams, some acetylene regulators are identical to propane ones. If you insist on using an acetylene regulator on propane, you must check the diaphragms and seals are the same parts as propane, as propane will degrade some kinds of rubber. Really, just but a propane regulator unless you’re trying to reuse an acetylene regulator you already own. If you do already have an acetylene regulator there’s a decent chance the internals are the same. Smith for example lists one regulator as LP or acetylene, but check before buying. Harris told me the 15 psi version of the 25GX would be better suited for this application. Don’t buy a random old acetylene regulator and use it with propane.

Harris and Smith are good brands, Victor and Uniweld are okay. Avoid no-name cheap imports, although there are many other reputable brands that make regulators for scientific and industrial purposes, and torch regulators are relatively undemanding applications. I hesitate to even recommend name-brand imports like Gentec. I’ve had issues with Gentec valves before and while easy to test on a torch, are much harder to test on a regulator. Harris, Smith and Victor will make you custom scientific or industrial regulators for lots of money, but Harris gets the bonus points for actually publishing pressure rise data (as low as 0.2psi rise for a decrease of 100 psi in the tank) and caring about the performance for their torch gas single stage regulators, although they have an import regulator for sets. Every other company will just tell you to get dual stage if you want steady pressure. Victor also publishes limited pressure rise data, but the best one is a medium-small regulator with 0.5psi/100psi and it can be as bad as 4.8psi/100psi. Victor’s high end regulators are optimized for low droop which is the decrease in pressure at high flow rates, but don’t really affect flame stability once adjusted. Uniweld makes rather utilitarian regulators, although Ameriflame (Uniweld’s lesser brand) seems to be cheaper imports rather than rebranded Uniweld like some other Uniweld products. Any reliable regulator is fine.

Rubber diaphragms tend to to have less pressure rise, but stainless are arguably more durable, but really only needed for very hot/cold gasses. Plastic knobs/keys that cup around the bonnet are better than T-keys because they help shield the hole from grit and grime. Don’t get up in the idea that T-keys are better because metal is better. Light and light-medium regulators tend to be built for economy and may not hold pressures as well. Heavy duty ones are built for flow and may sacrifice pressure stability for higher flow, and at the very least, may not get you any better performance than a good medium duty one. Bigger gauges are easier to read but also add bulk. A low pressure 15 psi (dial is 30 psi but with half of it red because over 15 psi is dangerous with acetylene, might also have a pressure relief valve at 15 psi) gauge will be about twice as easy to read as a 60 gauge one, and the high pressure gauge doesn’t matter. Smaller 15 psi 2″ gauges are more useful than larger 2-1/2″ 60 psi gauges.

It’s not really worth dealing with an old used regulator. Their reliability is questionable, and these things are assembled with no oil or grease, so if the surface is tarnished, there’s a decent chance the threads are corroded tight and it will be a pain to try to clean and rebuild. Doubly so for an oxygen regulator because you run into the issue of getting it clean enough for safe oxygen use. I have some older dual stage acetylene regulators which I can’t get open and I had to destroy parts to remove NPT fittings.

Cheap option: Reuse a quality single stage propane-compatible acetylene or buy a new quality propane regulator (Harris 25-GX propane), plus WE brand flashback arrestor, don’t cheap out

Expensive option: New low pressure dual stage propane specific regulator plus matching brand flashback arrestor

Flashback Arrestor – Different ones work different ways, but they often have a stainless steel sintered mesh which will diffuse a flame and have a check valve to prevent backflow. You need one on the fuel line somewhere. Regulator and torch arrestors are not identical. They flow in opposite directions. Regulator arrestors will tend to be larger and have higher flow, but that doesn’t matter much on the propane side. Torch mounted arrestors can prevent hoses from exploding but add weight to the torch and are more restrictive. Torch mounted check valves are much lighter and can offer some protection, but are not a substitute for arrestors. Regulator mounted ones protect the tanks if you can somehow cut the hose and force oxygen into a positive pressure fuel tube, but also don’t add to the weight of the torch. Don’t skimp here and decide you don’t need one. Western Enterprise ones tend to be more affordable than torch company branded ones without venturing into unknown China direct territory.

Hoses

Hoses connect your gas supply to your torch.

WARNING: YOU MUST USE GRADE “T” HOSES!

Grade – You must use “Grade T” hoses because propane will degrade “Grade R” acetylene-only hoses over time. Just because acetylene is more exotic than LPG doesn’t mean grade R hoses are more exotic than grade T. Some people say you can use a “Grade R” hose if you replace them or purge the propane from them. You don’t want to second guess yours hoses, constantly check for leaks, or forget to maintain them. Torch kits also come with cheaper “Grade R” hose, so skip the kits. “Grade T” is what you need.

Diameter – 1/8″ is all you need for brazing. 1/8″ brazing hose is ridiculously expensive. Tinmantech used to sell some ultralight hose. Smith sells kevlar covered brazing hose. Jewelers have been know to use aquarium or lab tubing on little torches. Fittings can be obtained from knockoff little torches, but you’re playing with fire. 1/8″ makes a massive difference in feel. The difference is night and day. If you can afford it, you should buy it, it’s easier to learn on for the novice, and less fatiguing to use for the pro. 3/16″ is much stiffer, but much cheaper and much more durable. If you use 3/16″ it’s going to feel like you’re fighting the hose when doing delicate motions. 1/4″ even more so. These can be used if you just need to extend good lightweight hose with couplers, are prone to destroying equipment, or just can’t afford nice things.

Fittings – Fittings can be be “A” or “B” or one on each end. They need to match the parts they connect to. Tinmantech hoses are A size with B adapters for the regulator. They sell adapters, but adapters cost money and add bulk and the most compact ones meant for regulators are too big to fit torches. They will add a couple ounces to the torch. That is to say you really should get hoses with A fittings on the torch side. Save the B-B hoses as extensions.

Length – 12′ is good if you can wheel your setup closer to your frame. 25′ is good if you plan to keep it in a corner or next to a wall, but oxygen concentrators don’t like than and like to breathe. The Tinman tech ones are annoyingly 9′ long, which is long enough, but the extra 3′ would have been nice, especially since at least one brand of oxycon recommends open flame be kept at least 6.5′ away. No issue if extending it with a 3/16″ hose though.

Brazing hose is extremely recommended. It is one of the most noticeable equipment choices, and benefits the amateur and professional alike. It’s more comfortable and there is a large increase in dexterity, and therefore flame control, and therefore braze quality. This is not the sort of thing that you want to start cheap and replace when you get better, you want it now unless you really can’t afford it.

Cheap option: 3/16″ Grade T hose

Expensive option: Smith Kevlar or Tinmantech hoses + couplers + 12′ Grade T hose

Torches

You would think torches are really important, but they aren’t really. You still need to buy a good one that doesn’t leak and have good valves, but torches of a certain quality are all about the same. What you don’t want is a heavy duty or even medium duty torch. It’s excess bulk that serves no purpose except to make life harder, even if they are cheaper. You can use what you already have, but don’t go buying a new one because you can buy a set for the price of a handle at HF. The appropriate size is a light duty HVAC torch. They mostly have “A” fittings. People like to call them aircraft torches because aircraft used to be welded with them a long long time ago when they oxyfuel welded aircraft, but they don’t anymore, and most of these are sold for the much less glamorous industry of HVAC. Jewelers torches (“little torch” equivalents) can get just hot enough are also too small and compact and tend to get hot. A larger jeweler’s torch like a Hoke might work, but has less compatibility. It might be a good idea to get some torch side check valves as well, if not full flashback arrestors.

Torch handles are basically just handles, valves, and interfaces to connect to hoses and mixers/tips. So picking a torch is based on ergonomics, compatibility, and valve quality.

Note that there’s some false precision with the unit conversions and some of these are catalog, not real life, specs.

Smith AW1A(AW1)* – (146mm, 170g, OD 17.5mm) It’s nickel plated and looks great. It’s top quality and made in USA. It’s expensive and uses proprietary mixers. It’s light, but the coupling sticks out past the valves, and the handle length below the valves in on the short side, barely longer than a jewelers torch. You effectively lose about 20mm of handle, which makes it relatively cramped, and it’s more tip heavy. Expect the hose fittings to end up in your palm. Check valves can help extend the handle. The cylindrical part of the handle under the valves is ~90mm. The handle is a little fatter than Victor type torches. Mixers are chunkier too offsetting some of the weight reduction. You can turn the tips in the torch body while the torch is on because o-rings aren’t a taper fit like J-types, but you don’t really need to with light hoses (it’s basically not useful at all with light hoses). Tube-in-tube for high flow and a strong outer tube. They used to have lifetime warranties including wear and tear, but Miller got rid of that. AW1 is the old equivalent model, but also doesn’t have a lifetime warranty. Nickel plating means no coins smell on your hands. Even with these designations, the designs varied over time. It’s hard to justify the premium and incompatibility without the warranty and higher prices. My old torch was a Smith though and I did like it. To me, the valves feel very nice despite with smooth even action and little backlash. They’re very attractive and just feel very well made and exclusive with that bright shining nickel plate instead of looking like a black tarnished bathroom fitting after 10 years. It’s like the Campy of torches, great quality, great fit and finish, bling, timeless, unique, exclusive, proprietary and not really any better in practical terms, even worse in some ways.

Special Features:

Lightweight

Nickel Plated

Must use Smith AW specific mixers

Can rotate tips with flame on

Valve knobs engraved

Female threaded body

Short Handle

Meco Midget* – (170g) It’s somewhere between a jewelers torch and an aircraft torch. Unlike most aircraft torches, it can’t take a cutting attachment, but you don’t need that for frame building and a little oxygen generator won’t be able to keep up. It uses its own tip system, but the tips are very good and many of the upgrade tips are threaded to the Meco standard. It does not require a tip adapter, so it’s really closer to 110g for comparison’s sake. The shape is very different from the others though, it’s more rectangular than cylindrical. One interesting quirk is the long valve barrels allow for anti backlash springs, so I would expect the valve action to be very good. Some people like it, some people don’t. It’s fairly expensive though. It’s like a mini-velo, quirky and compact, some people love them and it’s perfect for them, some people hate them and it’s literally all just disadvantages with no redeeming features. Or maybe Huret, it’s just weird and different.

Special Features:

Featherweight

Antibacklash valve springs

Integral mixer and tip tube

Uses Meco or Paige tips without any additional adapters

Extra short and flat body

Victor/Turbotorch J28(J27 etc) – (152mm, 241g, dia 15.9mm) Most of the other torches in this list are modeled after Victor J series torches. It’s the “original” and 28 is the current production version. It’s a little heavier, but you’re not throwing your torch in the back of a truck, so extra strength isn’t needed. Tube-in-tube for high flow and a strong outer tube. The hook created by the offset fuel fitting feels nice in hand with a finger resting in it. Victor advertises built in check valves and flashback arrestors on most torches, but the J28 does not have them. Victor used to be made in USA, but no longer. Unlike some companies, they didn’t keep the quality up either, despite charging a premium. They’re still good torches, but it’s hard to say they’re still top shelf and worth the top shelf price. If you have an older J torch, use it, otherwise, don’t buy Victor new. They are one of the biggest if not the biggest name in oxyacetylene torches, so if you happen to receive a second hand torch, there’s a decent chance it’s a Victor and there’s no shame in using a Victor, but Smith has commonly been seen as the more premium of the two and it’s just a quirk of marketing that Victor is now more expensive in addition to not being made in the USA. Most of the other torches below will be described in relative terms. The Shimano of the torch world, the standard setter, sturdy and reliable, or at least it used to be until quality started slipping, just like Shimano.

Special Features:

Ball bearing tipped valves

Contoured handle at hose fittings

Uniweld/Ameriflame 71* – (152mm, 181g) Victor J type torch. It’s a bit lighter with a larger handle and not as strong. I think it’s twin tube construction but it doesn’t impede flow. The design itself is derivative of older Purox W-200 torches, but has Victor tip compatibility. Still made in USA. Different vintages come with different knobs. Uniweld tends to be not top quality, the construction and fit and finish isn’t as nice as others, but it’s still good and tends to be a bit more affordable. They have aluminum valve knobs which have a tendency to rarely fall off the needles rendering the torch useless and possibly dangerous, but I’m pretty sure this happens when the torch is mishandled and not in normal use. It’s a bit less sturdy and easier to dent, so don’t abuse it, but you should understand the compromises between strength and weight as a framebuilder. Still better and cheaper than a “genuine” J28. Maybe something like older SRAM without the high tech gadgetry. Nipping at Shimano’s heels and chasing Victor’s coattails, a bit cruder, but also a bit lighter. It doesn’t really fit. Maybe more like Suntour, smaller company, less marketing, less polish, but better in other ways, lighter and cheaper with solid performance.

Special Features:

Lightweight

Ball bearing tipped valves with large aluminum knobs

Slightly larger body diameter

GOSS TW-5A – (152mm) There’s not a lot of info on these nor do they seem to be widely available online. Made in the USA. I have not seen one or handled one in person, although I have some GOSS tips. They used to also make third party Smith compatible tips. The knobs are labeled with stickers and knurled, but use a regular needle design without the ball bearing tips. The construction is twin tube like the Uniweld, but it has brass knobs meaning it is likely heavier. It doesn’t seem bad for the price and I wouldn’t turn one down. Based on the picture, I think that this may be the fattest torch in the line up if you don’t like your torches too skinny.

Harris 15-5(15-4 etc.) – (146mm, 230g) 15-5 is the current version, there’s a Harris 15-4 etc. Some say it is supposed to be Victor J compatible but it doesn’t seem to be. Harris also used to make torches sold as Craftsman. The HV V-series variant may be Victor J compatible and seems fine as a Victor variant. Harris seems to make torches in all sorts of random countries. Buy a Harris torch of unknown vintage and it was probably made in Europe somewhere. Buy another one and it was in a different European country. Buy another one and it was made in USA, because you might not have realized it from the European manufacture, but Harris is an American company. At one point they used to advertise “Made in Europe” for torches. Bizarre. Harris has a injector mixer which is good if you’re pairing it with city gas and not propane, and you also don’t have to walk the flame up alternating increasing oxy and propane, but you need high oxygen pressure. You can use it if you have one, but Harris torches are too expensive for no reason to buy new without any justification. This is more of a use it if you have it torch. That being said, Harris Safety-Silv silver fillers and fluxes are great. It’s that weird “boutique” CNC component company that is inexplicably more expensive despite offering nothing and they don’t even look that good.

Special Features:

Color coded valves

Must use Harris specific mixers

Harris 50-10 – (203mm, 360g) Not a J type torch. It has “B” fittings and is called medium duty, but it just about aircraft size. It uses different mixers. It gets a mention here because it has a neat gas saver lever that turns off the gas except for a small pilot light. Notably heavier however. Only buy if you are loaded.

Special Features:

Relatively heavy

Color coded valves

Must use Harris specific mixers

Has shutoff lever

B hose fittings

SUA Ligth[sic] – (150mm, 246g) Victor J type torch. Less than half the cost of others but of lesser quality. Sold on Amazon for easy returns though. If not, return and try again. The fit and finish is decent with no sharp edges or rough spots, but it’s clearly not the equal of better torches. Valves are not the smoothest or most consistent, but there’s a packing nut to make sure it doesn’t leak. There’s about 1/4 turn worth of backlash, which is annoying given that it only takes 1/8 of a turn for full oxygen, however you can feel when the threads start engaging properly or you could always press down or pull when adjusting the valve. All torch valves have backlash, but the straight shaft packing and lower quality makes it readily apparent here. Inexplicably, the base is at a random angle compared to the valves, which the brand says is normal. The color coded dots are just sticker adhesive. The Victor style hook created by the offset fuel fitting feels nice in hand with a finger resting in it. I think it’s functional, but you’ll notice the quality of better ones. One thing I actually quite like about it, although it looks crude, is how far the valves stick out. It lets you rest your fingers against the stem under the knob with little risk to touching the knob, giving a very roomy feel to the handle. The valves are very chunky, and the torch feels very solid. I don’t think it’s going to spontaneously fail, nor does it feel like it’s going to break. I think you might get upgradeitis and not like the valve action. If it weren’t for the random body angle and the bad valve action, I would actually recommend it since there are things I like about it. I would say save up a little and buy yourself a keeper. Also seems to be sold under the VEVOR brand. That no-name department store derailer that maybe works, maybe it doesn’t, maybe it’s practically the same as a Shimano Altus.

Special Features:

Extra long color coded valves

Contoured handle at hose fittings, but at an odd angle

RXWELD/AWLOLWA Ligth [sic]- I don’t know anything about these other than they’re about $70 with 3 tips on Amazon. They look like a more faithful Victor clone than the SUA. Come with check valves, but I don’t know how much I trust no-name safety equipment when Western ones are pretty cheap. May or may not be decent, but no warranty and no company to stand behind it, so don’t expect quality.

Special Features:

Ball bearing tipped valves

Contoured handle at hose fittings

Gentec 140 – (152mm, 241g) Victor J type torch. Made in China, but okay quality. Not top shelf though. Not immune to issues but has a warranty at least. It’s the closest to being a J28 clone. The Victor style hook created by the offset fuel fitting feels like in hand with a finger resting in it. It is also sometimes sold bundled with screw on check valves which tends to be cheaper than buying them separately, but the body itself is the same. Like Microshift, makes some faithful Shimano clones, but also chooses to innovate from time to time.

Gentec 342T-F* – (168mm, 318g) It’s like the Harris 50-10 gas saver torch except with Victor J tip compatibility and a lot cheaper, but still more expensive than plain Victor J type torches. If the novelty of a built in gas saver intrigues you, this makes a lot more sense than a Harris 50-10. Slightly lighter than a 50-10 but still heavy.

Special Features:

Relatively heavy

Has shutoff lever

B hose fittings

Gentec Compact* – (112mm, 100g)It’s a hybrid of their jewelers torch but with Victor J tip compatibility and improved flow from J type mixers. It comes with 1/8 hoses and is very light and small. The tips for it are exceptionally light, but short and the biggest tip they advertise for it is a #2 equivalent, but you can fit J type bigger tips to it. I think the construction is twin tube and flow is compromised due to the small size and jewelers torch valves, but seems to have a max flow about 7 LPM at a pressure of about 7.5 PSIG. Max flow at 20 PSIG is over 10 LPM, so it’s not too small to be used with either size of concentrator, but on the small side. The valve knobs are color coded but small in diameter and packing tightness is unadjustable and threads are more exposed to grit, although the packing itself is well protected. The smaller valves do have an advantage though, it’s about 1/4 turn instead of 1/8 turn for max oxygen like on other torches. Seems similar to a Messer MINITHERM, although Gentec made a version of with with a different head as a little torch equivalent. Although the measurement is short, I only measured the body without the barbs, and the handle length below the valves not including the fittings is a hair longer than the Smith AW1 and a hair smaller in diameter. Basically it’s cramped, but only as cramped as a Smith AW1A. Sold as a premium lightweight alternative to the Gentec 140 J type torch for HVAC. Barb fitting means less weight by an ounce give or take due to lack of real hose fittings, but also prevents the installation of check valves. Newer Gentec Small torches might share the design, but with a little torch adapter included, although Gentec won’t confirm this. Older Gentec Small torches do not share the double o-ring design and are only little torch tip compatible. The valve quality doesn’t seem great, it’s okay. Consider that Smith brazing hose costs nearly as much as this torch that includes hoses though, and it is still more nimble than any of the other torches with Smith brazing hose.

Special Features:

Featherlight

Chrome plated

Colorcoded valve knobs visible from any angle

Small valve knobs

Valves without adjustable packing

Short handle

Barb fittings with included 1/8″ hoses

| Length | Weight | Diameter | Tip Compatibility | Hose Fitting | Finish | Valve Knob | Warranty | Origin | Approx Price | |

| Smith AW1A | 146mm* | 170g* | 17.5mm | Smith AW/AT | A | Nickel | Engraved Nickel plated | 5 year | USA | $160 |

| Meco Midget | 70/171mm* | 170g* | N/A | 1/4-28 | A | Brass | Brass | USA/Mexico | $250* | |

| Victor J-28 | 152mm | 241g | 16mm | Victor J | A | Brass | Brass | 5 year | Mexico | $185 |

| Uniweld 71 | 152mm | 190g | 19mm | Victor J | A | Brass | Aluminum | 1 year | USA | $110 |

| GOSS TW-5A | 152mm | Victor J | A | Brass | Labeled Brass | 3 year | USA | $70 | ||

| Harris 15-5 | 146mm | 230g | B-15-3 | A | Brass | Color Coded Brass | 1 year | USA | $200 | |

| SUA (VEVOR?) Ligth[sic] | 150mm | 246g | 17mm | Victor J | A | Brass | Color Coded Brass | 30 day | China? | $45 |

| RX WELD/ AWLOLWA Ligth[sic] | ? | ? | ? | Victor J | A | Brass | Brass | None | China? | $70 w/ tips |

| Gentec 140T | 152mm | 241g | Victor J | A | Brass | Brass | 2 year | China/Taiwan | $90 | |

| Gentec Compact | 112mm* | 100g | 17mm | Victor J | 1/8″ Hose Included | Chrome | Color Coded Aluminum not adjustable | 2 year | China/Taiwan | $170* |

Torch handles really don’t affect performance much, and many of them are very similar. You could buy based on the above chart, but in the end you basically buy one that matches your personality or build philosophy and doesn’t leave you wanting to upgrade later. There is no perfect torch. For every single one of the above torches, I could tell you a reason it’s better and a reason it’s worse, and how it really doesn’t matter much.

Warranty details vary, and warranties are sometimes counted from date of manufacture.

To breakdown criteria:

Length is length, although, the compact torch and Meco are measured slightly differently. The AW1A’s layout puts the valve lower making the handle feel more cramped. Both the AW1A and compact torch are ~90mm below the valves, and ~15-20mm shorter than the alternatives, although the AW1A can be extended with check valves if you’re willing to grip those. If it weren’t for the short grip/valve placement on the AW1A, it would be my top pick despite the cost and proprietary tips. It doesn’t matter if using a pencil grip. Aircraft torches are already on the short side, so I feel in general, longer is better, none of them feel too long.

Weight is weight, although this doesn’t tell you anything about balance. Some weights are not directly comparable, for the Meco and compact torch. Generally the lighter the better, you can also feel differences in weight distribution. Generally, lighter is better, but I wouldn’t obsess too much over it. Even the heftiest torches here are not especially hefty. Hose weight has a bigger impact, and a light handle with screw on tips feels a little worse balanced with heavy hose.

Diameter is diameter. All of these are very similar in diameter, although I think the Harris is the largest. Diameter is personal preference, larger fills up the hand better and gives you more torque, smaller makes it quicker to roll, but these differences are marginal given the spread of diameters. Within the range of aircraft torches, bigger diameter is better, none of them feel too big.

Tip compatibility determines what tips or what adapters you need. Victor J style tips are the most common. Smith and Harris tips tend to be heavier in both the mixer and tubes. The Smith tips let you turn the tip while the flame is on, and it the connection feels more solid because it isn’t sitting on o-rings. However, the external mixer threads are more vulnerable if swapping between tips. External threads on the torch will usually have a union nut on them and will be more likely to be protected, although the torch is more costly to replace if damaged. Smith’s tips end up having a big heavy mixer, and mess with the valve placement on the Smith handles. Victor’s and Harris probably have a more reliable seal when it comes to dealing with wear due to the taper, but probably a less reliable seal when not tightened properly and they seem to never fit super tight or firmly. If I had my choice in mixer interfaces on technical merits, it would be Purox style, which is stepped instead of tapered, but that just isn’t industry standard.

Hose fittings are usually the smaller A size paired with 1/8″ or 3/16″ hoses. They make it difficult to fit torch side flame arrestors which protect hoses from exploding, but those also add weight and bulk. You don’t really want to run adapters because they add weight and bulk. The only exception for this is the compact torch with has barbs. That means check valves can not be added, but it also means the hoses are a bit lighter due to not needing threaded connectors. Check valves can be added to the AW1A helping to offset the short handle length. Victor J28 and the closer J types (Gentec 140T and SUA Ligth) have offset fittings so it creates a nice little finger hook on one side, and is flatter on the other side for improved ergonomics.

Finishes affect the look, but some people also have allergies to different metals. Brass is an alloy of copper so could affect people with copper allergies. Brass can also result in metallic old coin smell on your hands since many coins are also copper alloys. Brass will tarnish dull and brown over time, nickel and chrome might wear or peel over time exposing the brass underneath. If not allergic, I feel that plated is superior.

Valve knob styles vary in design. It’s nice to have one with clear indexing features so you can easily turn 1/8 of a turn or something, which the Meco and compact torch lack. Color coding is safer, followed by engraving. The packing on most valves can be tightened with a nut, adjusting how much friction there is on the valves and letting you tighten in case of leaks, the exception being the compact torch. Most modern valves have packing for a straight smooth valve stem, so making them tighter does not help with backlash and just increases friction. More precise threads result in less backlash, and finer threads result in less adjustment per radial unit of backlash. Some older torches, like over AW1s have threaded packing, which are more prone to wear, leaking and contamination, but also can reduce backlash when tightened and higher friction sensitivity to packing tightness.

Warranty policies vary, be sure to examine the warranty policy. Many start from date of manufacture, not date of purchase. Some companies will RMA/RGA with a prepaid label, some won’t, some will do an over the counter swap at your local distributor, some won’t. Smith used to have both a lifetime warranty and service plan, but I’m not sure Miller honors it anymore, even for lifetime marked torches.

I also have a preference for fluting on the Smith , followed by Uniweld. The angle and corners of each spline is less sharp, but they provide adequate grip. Victor, Gentec and SUA have grooves that feel like right angles with a pattern that’s like a square wave wrapped around the handle. It might provide more grip, but I don’t like the feel barehanded, especially pencil grip. The Uniweld splines are more like a skiptooth pattern, so the handle tends to feel lumpy and polygonal when rolling it in your fingers, again, especially with pencil grip. I tend to not like fine knurling like on the Harris either because the teeth tend to be sharp triangles and they trap oil and grime.

China is capable of making things just as good as things made in the USA, but my feeling is all the torches listed here not made in USA did so to cut costs and quality. I don’t feel any of the non-USA torches are just as good but less expensive, as might be true of other Chinese made products. Quality also varies between the US brands. An import torch may be of adequate quality however, so I wouldn’t let origin scare you from a torch, just realize that lower quality usually comes with lower price. They’re cheaper for a reason and you don’t really get more bang for your buck, although between all these options, you don’t always get what you pay for either.

The asterisks in the chart above merit some important notes. Smith AW1A torches have their valves about 20mm lower, so the handle length feels shorter and more cramped. The Gentec Compact torch is measured without the barbs, and the cylindrical part of the handle below the valves is essentially the same size as the Smith AW1A at around 90mm, which is maybe 20-25mm shorter than the handle of other torches. A Smith mixer also seems to weigh 10-20g more than the equivalent J type mixer, and even though it runs a skinnier 1/4″ tip tube, they often are no lighter than 5/16″ ones. Think oversize thinwall tubing. The Gentec Compact comes with 12′ of 1/8″ lightweight hose. The Meco comes with a 4″ tip tube included and the mixer is integral to the design, so the length of the handle is very short, and while expensive, is not as expensive as it might first appear.

If you pride yourself on fine craftsmanship and make refined and luxurious bicycles it’s the Smith or Meco. Yes Victor and Harris are more expensive than Smith, but no, they aren’t as nice as Smith. Smith is a genuine top shelf torch that also doesn’t make your hands smell funny if you handle it without gloves. As much as I like Smith torches, the proprietary mixers, the limited tip options, the lack of length etc. bother me. The quality is superb, it’s just not perfect and better in every way. Meco suffers from similar weirdness and incompatibility.

If you fancy yourself a no-nonsense builder that focuses on performance, versatility and/or function, it’s the Uniweld 71. I think the aluminum knobs are a bit of an eyesore, but brass is even heavier than steel. It would still be a top pick among J type torches even if they were all the same price and all made in USA. It’s not necessarily better that every torch in every way, but if there isn’t something specific you want from a different torch, this would be the one. It’s all around good even if it doesn’t exude the same sense of elegance and excellence that Smith does. There’s few things to dislike about it, and it’s good in directly comparable metrics like weight, length and diameter. Although there’s no shame in using a Victor if you already have one, especially an old made in US one.

If you’re cheap stingy hobby builder on a shoestring budget and aren’t selling MUSA and don’t buy MUSA, it’s the SUA. Try explaining to a customer paying premium custom bike money that you use cheap pretty okay equipment and they’ll wonder if they’re buying a cheap pretty okay bike. For that reason alone it’s a waste of money for a pro builder. The build quality isn’t really there. It feels sturdy enough, the fit and finish is actually nice enough with burs and flash ground down, you can adjust the valves so they don’t leak, and it seems like it would do the job, but the valves aren’t refined and the fact that the head and lower body are at a random angle relative to each other means you might find yourself wanting to upgrade in the future.

If you inherited a torch from somewhere, it’s probably a Victor and there’s nothing wrong with a Victor. They’re common and plentiful on the second hand market, although I would advise against second hand purchase in general. Despite it sounding like I have nothing good to say about Victors, older Victors are actually nice, and there’s no shame in owning a Victor, I just don’t feel they’re worth the cost of entry and other torches are at least as good in many ways. The little finger hook the hose fitting makes feels really nice in hand with the right grip, it’s something I miss on other torches. If I had to own a torch with that feature and cost wasn’t an issue, it would probably be a Victor. If I already owned a Victor I wouldn’t spend money on a Uniweld.

If you’re a maverick, it’s the featherlight Gentec Compact or the Meco, these are torches with their own pros and cons and not just the same as the others. It’s worth noting that the Meco includes the mixer and tip tube in the weight and price, and the Gentec Compact torch includes 1/8″ hoses to fit the barb fittings, but can’t fit check valves. Like the Smith, the Gentec is plated, so no smelly hands. These aren’t directly comparable in terms of price or features. They’re both small, but will also end up around 100g lighter than other setups at less than 200g without hoses.

If you’re buying from your local welding store to support local businesses or for warranty reasons, it’s one of the other brands.

No specific recommendations except that some torches are not good values. Asterisk means worth considering. Uniweld 71 is the Victor J style torch of choice, the others are not strictly Victor J type torches but still worth considering.

Tip Tubes & Mixers

Selection of propane specific tips tends to be bad and requires a mixer and adapter tube that works with threaded nozzles. This removes the ability for tool free tip changes (the big advantage of a modern double o-ring design) unless you buy lots of tip tubes.

Some torches have built in mixers. If you are planning on using threaded nozzles, you are basically converting your HVAC torch into one with a built in mixer. The fact that mixers are attached to tips is a quirk of the fact that these torch handles were designed to take oxygen cutting attachments, which use a completely different mixer design. It also allows for some tuning of the mixer to the tip, and easy swaps between EP and injection mixers, but having a built in mixer like a Meco is not really a disadvantage. Being able to swap between a cutting head and welding tips without tools or needing to leak test was a big advantage back in the day, but adds pointless bulk and complexity if you’re only going to swap using the threaded tip interface. It offers us no advantage unless you keep multiple mixer-tips around for toolless quick changes, which is why I’m an advocate of having multiple mixers.

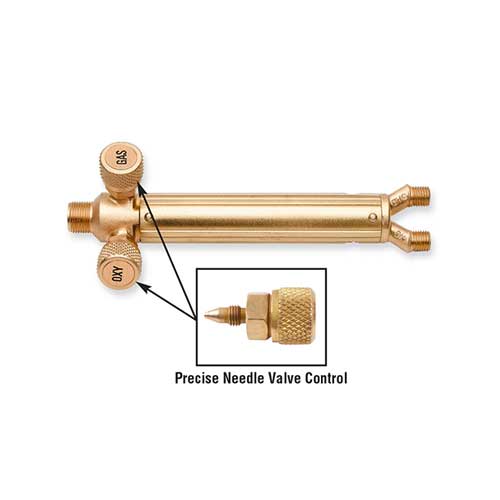

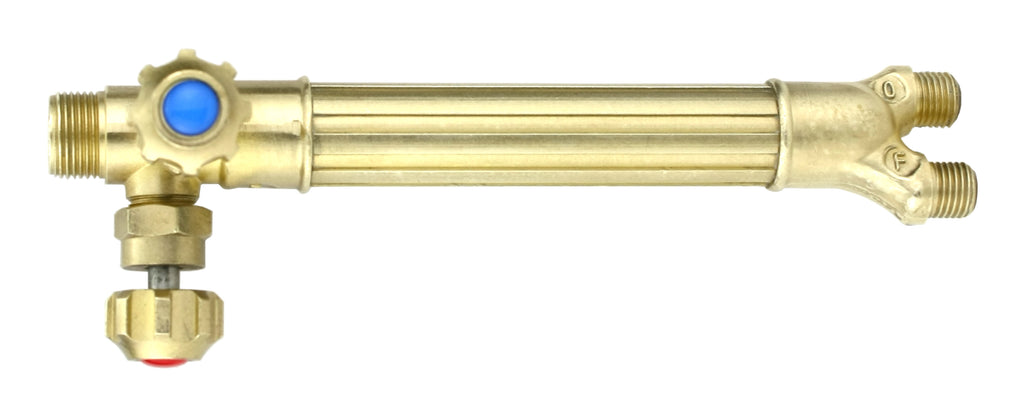

There are two types of mixers, injector and equal pressure. Most normal acetylene torches and tips use equal pressure mixers. Alternative fuel mixers may be of the injector type. It has been stated that propane mixers have more oxygen holes because of the increased oxygen requirements, the problem with this being that oxygen is usually run through the center hole. Injection mixers rely on the venturi effect with high pressure oxygen to pull low pressure (0.25-2psi) fuel gas, common with “city gas” coming from pipes or piped in propane, or in ye olde velocipede times, low pressure carbide acetylene generators. Injectors have small orifices to speed up the oxygen and reduce pressure for the venturi effect, meaning that it will have less maximum oxygen flow for any given pressure level, but low restriction for the fuel. In other words, if you want a big tip with a big flame and only a 5psi oxycon, an equal pressure mixer is more likely to allow sufficient flow than an injector.

Which style is better is debatable. There are people who assert that one is safer than the other. Some assert injector is safer because is requires oxygen to pull the fuel. Some assert equal pressure is safer because the high oxygen is more likely to cause backflow into the fuel lines. Injector mixers are supposed to be used with high oxygen pressure and low fuel pressure, although that never stopped anyone from treating it like an equal pressure mixer (effect lessened when fuel pressure is higher and the oxygen isn’t pulling the fuel). When used as an injector mixer, there is less alternating between fuel and oxygen adjustments to get the flame bigger because more oxygen will tend to pull more fuel along with it. Equal pressure is typically capable of more intensive applications, of which bicycle brazing is not. The big issue with using injectors is they usually expect high oxygen pressures our oxycons simply don’t have. If running 5psi, an injector mixer could become a bottleneck limiting the amount of oxygen delivered and therefore reducing the maximum flame size even if a bigger tip is used. Not all injector mixers are excessively restrictive though.

Smith designs in general seem to be based off of an injector design, but tuned differently. There’s an injector cone on the bottom which is meant to accelerate the oxygen through a small hole past a gap that fuel can get in. One old 60’s era smith tip and mixer I tested behaved like an injector without a nozzle, but had backpressure on the fuel side with the nozzle.

Mixers and tip tubes listed here are purely informational. Only adhering to manufacturer’s recommendations for propane is advised.

Smith AT61 – Injector style mixer. Only compatible with Smith AW1A and threaded for 1/4-32 at the end. Smith tips for this adapter are bad, so you will almost certainly be using this with a paige NK adapter and paige or meco tips. You may want to try turning down the pressure to 2 psi and see if the oxygen pulls the fuel. At one time it was advertised as working down to 0.25 psi of fuel pressure, but it’s hard to get a straight answer from them. It could very well be that the only reason AT61 was originally recommended for propane/natural gas is because of low pressure piped in propane/gas for buildings. I’m not sure if anyone is really keeping up with Smith technical stuff over there since Miller bought them.

Smith AT60 – Equal pressure(?) style mixer. Similar to mixers on AW tips. Way back when, Smith used the same mixer for propane as acetylene. Only compatible with Smith AW1A and threaded for 1/4-32 at the end. Similar to above. Smith tips for this adapter are bad, so you will almost certainly be using this with a paige NK adapter and paige or meco tips. Smith says for acetylene though, but the Versa-Torch compatibility illustration is completely arbitrary with some tips being acetylene only, but those same tips being fine for either when attached to a twin flame attachment. I don’t really know that it would be that different from modifying a decently large Smith tip.

Victor UN-J – Equal pressure(?) style mixer. Compatible with Victor J type torches and threaded for 5/16-27 at the end. Victor says it can be used with acetylene or propane (or hydrogen or natural gas). Possibly has more fuel holes simply so it can have enough flow for the biggest tips. The Gentec one is about half the cost from the right vendor, but are basically the same.

Victor UNN-J – Injector(?) style mixer. Very hard to find and very expensive. Compatible with Victor J type torches and threaded for 5/16-27 at the end. Victor specifically says for use with low pressure natural gas 2 psi or under, although also lists it as multi-gas in some places and propane/natural gas specific in others.

Gentec 881W – Clone of Victor UN-J for half the price, but maybe doesn’t have the spiral mixer.

Harris B-15-3 – Equal pressure style mixer. Compatible with Harris 15 torches and threaded for 5/16-27 for the tip tube. Contrary to other sources, I did not find Harris 15-3 mixers compatible with Victor J type torches. You will have to find a compatible tip tube, and Harris ones require Harris tips, although Harris does have alternative fuel specific tips.

Harris B-15-3S – Injector style mixer. Compatible with Harris 15 torches and threaded for 1/4-32 (nonstandard) for the tip tube. Contrary to other sources, I did not find Harris 15-3 mixers compatible with Victor J type torches. You will have to find a compatible tip tube, and Harris ones require Harris tips, although Harris does have alternative fuel specific tips.

Harris B-15-3F – Injector style mixer. Compatible with Harris 15 torches and threaded for 1/4-32 (nonstandard) for the tip tube. Contrary to other sources, I did not find Harris 15-3 mixers compatible with Victor J type torches. You will have to find a compatible tip tube, and Harris ones require Harris tips, although Harris does have alternative fuel specific tips.

Welding City J – Equal pressure style mixer. These can be salvaged for mixers and only cost $10-11 shipped. Threading is 1/4-26(? — seems slightly coarser than 27 and slightly finer than 1mm) and J compatible, but tip tube is threadlocked. It could also be 1/4″x1.0mm, like the opposite of Campy M10x26tpi, since this is used by SUA. Quality is low, but adequate. Claimed to have a spiral mixer, but doesn’t. The fuel gas holes are inexplicably randomly spaced and not the same mixer to mixer. Unsure if all mixers have the same number of fuel holes, size 2-4 have 3 and look more or less the same.

SUA/Mundaka J – An alternative to Welding City tips, but slightly more expensive. Not sure why you would buy these over Welding City tips except if you insist on buying the SUA torch handle with tips combo. 1/4″x1.0mm threading. They do make some cheap rosebuds though.

Gentec CMP – Injector style mixer. These come on the compact torch tips. Threading is M6x1 and J compatible, but tip tube is threadlocked. They are extremely compact and light, but the oxygen hole is excessively small, and the size 6 only flows ~3.5 LPM at ~8 psi and ~6 LPM at ~20 psi. Size 7 may be a bit better, but these tips call for 25-30 psi of oxygen.

Additional note, there’s a lot of thread sizes for elbows. For 1/4″ tubes, 27tpi such as Victor and Victor clones like Uniweld, 28tpi such as Smith and 32tpi for Harris are commonly used. Welding City seems to measure 26 tpi or so? For 5/16 tubes, 27tpi is most common, but there’s also 22tpi, and some vintage Smith tips have 5/16 elbows. Metric elbow threadings seem to almost always be 1mm pitch however.

I can’t recommend anyone do this, but I like tool-less tip changes because tool-less tip changes mean I’m more likely to actually change tips and I don’t need to keep a wrench around to remove hot tip parts and do leak tests. I don’t want to pay for a half dozen 881Ws plus adapters, so I have a bunch of #3 and #4 Welding City and GOSS mixers that have been repurposed to fit propane tips on the end. Even if the connections aren’t as good as the real thing, once the tips are on and leak tested, you leave them alone and stop any additional wear on the tip/tube interface.

Cheap option: Gentec 881W or adapt tips

Expensive option: Try a compatible injector and EP mixer and see which one you like better then report back, although this is really unnecessary. The Smith AT-61 is expensive, if running the Smith torch.

Tip Nozzles

Oxy propane tips come in 3 varieties. Repurposed oxy-acetelyne tips which just have a single plain hole (Smith). These will not be discussed here because if you have the money for Smith you have the money for better tips, but it’s advised to size up a couple of sizes with propane vs acetylene. Uniweld recommends 1 size up. The second are ones with a counterbore (Victor/Gentec TEN tips). Harris 1390N tips also have a counterbore, but have limited compatibility due to threading. Some people modify oxy-acetelyne tips by making a shallow counterbore twice the diameter of the orifice. This helps keep the flame attached and helps prevent it from blowing out. Propane has a lower flame speed than acetylene so the flame has a tendency to want to just float away when maladjusted. These are equivalent in orifice size to ones without a counterbore. The third has a ring of smaller holes around the main orifice (Meco, Paige, Welder’s Warehouse, H01) which gives even better performance and a sharper flame. Orifice is smaller for the same amount of heat because of the extra flames from the sides and because the pilots allow you to push more pre-mix through the center.

| Carlisle | IMPGEN | Meco | Welder’s Warehouse | H01-6 | H01-2 | H01-2 (Alt) | Hoke | Paige | Gentec | Victor | Harris | Smith | Welding City | SUA | |

| Link | Website | Website | Website | Website | Website | Website | |||||||||

| Threading | 1/4-28 | 1/4-28 | 1/4-28 | 1/4-36(?) | M8x1 | M6x1 | M6x1 | 3/16-40M(?) | 1/4-28 | 5/16-27 | 5/16-27 | 3/8-24M | 1/4-32 | J mixer | J mixer |

| Style | Knurled Pilot | Knurled Pilot | Knurled Pilot | Fine Slotted | Coarse Slotted | Coarse Slotted | Coarse Slotted | Hexagon Pilot | Hex Pilot | Counterbore | Counterbore | Countersunk | Plain | Plain | Plain |

| $26-35 | $30 | $30 | $8 | $2 | $2 | $2 | $6 | $20 | $15 | $25 | $10 | $10 | $20 | ||

| Origin | USA | USA | Mexico/USA? | Taiwan? | China | China | China | China? | China?(CIXI HC) | China? | Mexico? | USA | USA | China? | China? |

| Rack Fillet/ Braze-on(XXS) | OX-1 (28) | OX1 (28) | OX-1 (28?) | #1 (28) | #3 (28) | #1 (28) | #2 | TEN-0 (35) | TEN-0 (35) | 2N(35?) | 0-W-J | ||||

| Fillet/ Braze-on (XS) | OX-2 (35) | OX2 (35) | OX-2 (35?) | #3 (35) | #1 (35) | #5 (35) | #3 (35) | Pencil (37) | #3 (35?) | TEN-1 (40) | TEN-1 (40) | 3N(42?) | 1-W-J | #1 | |

| All-purpose (S) | #2 (39) | #4 (39) | Small (41) | #4 (38?) | TEN-2 (46) | TEN-2 (46) | 2-W-J | #2 | |||||||

| All-purpose (M) | OX-3 (46) | OX3 (43) | OX-3 (42) | #5 (43) | #3 (43) | #5 (43) | Brush (47) | #5 (42) | 4N(52?) | 3-W-J | #3 | ||||

| All-purpose (L) | OX4 (52) | OX-4 (53) | #7 (55) | #5 (51) | TEN-3 (60) | TEN-3 (60) | 5N(60?) | 4-W-J | #4 | ||||||

| BB/Crown (XL) | OX-4 (60) | OX-5 (63) | MA-1/MA-2 | TEN-4 (73)/883TEMFN-5 | TEN-4 (73) | 7N(76?) | NE153(86) | MFA-J #4 |

Many Gentec tips made in China, uncertain if TEN tips made in China

Paige lists CIXI HC of China as manufacturing partner on Etsy

Meco torch is “Made in USA, Assembled in Mexico” like some Victor products, uncertain where Tips made

Welder’s Warehouse region of manufacture and threading information is second hand, they will no longer disclose this info

H01 tips come from Aliexpress, it’s a safe assumption they’re made in China

H01-2 variant I received seems to have #4 as ~1mm, the brand you actually get is highly variable

There is some uncertainty if threads said to be 1/4-28 are actually 1/4-27

| Brand | Size | Orifice | Propane (~LPM) | Oxygen (~LPM) | |

| XXS | Harris | 2N | 35? | 1.5 | 6 |

| S | Harris | 3N | 42? | 2.5 | 10 |

| S | Victor | TEN-2 | 46 | 1 | 3.5 |

| L | Harris | 5N | 60? | 2.7 | 11 |

| L | Victor | TEN-3 | 60 | 1.5 | 4.5 |

| XL | Harris | 6N | 3.1 | 12.5 | |

| XL | Victor | TEN-4 | 73 | 4 | 11.5 |

Tip Sizes

All-purpose means all-purpose. This goes for S/M/L. They can be used for the other tasks and a frame can be fully built with TEN-2 tip (or 3 or 4 for that matter). It is not uncommon to settle on one size for everything. The other tips are nice to have. You don’t need to worry about S/M not being hot enough, they are hot enough.

S is superior for fillets because fillets benefit from precise flames, especially with propane which lacks the very hot inner cone of acetylene. The same precision also helps with filling stay and fork ends. Again, S is still hot enough for everything, but precise flames result in slower heating times and hotspots when trying to bring things up to an even heat. S heats the slowest making it “safer” when it comes to overheating but also heats locally making it harder to heat evenly. The main benefits are better fillet and filling performance, but if your frame doesn’t use those methods or you use an XS tip for those, then these aren’t beneficial. The S tip is the tip that’s on the small side but hot enough to comfortably perform framebuilding brazing. That being said, S is lacking from a lot of vendors where each size up is +25% or +15% up (which is what victor follows except when they decide to skip a size). Note that even a S or XS piloted tip can sometimes max out a 5L concentrator, but the flame maybe be turbulent at the far end, which produces lots of heat, but in a flame that doesn’t wrap as well.

L is for people who want a hotter flame to work faster for production or to try and minimize HAZ area (heat takes time to spread, think frying pans and hot spots). The large flame makes it easier to bring an larger area up to even temperature, which is a benefit to sleeved/lugged joints. L also runs an increased risk of overheating and creating embrittled steel when trying to apply localized heat. L is also good for fork crowns and lugged BB shells. You don’t need your all-purpose tip to be good at these things if you buy specialized tips for them though. You may prefer a S or L tip if you prefer to to these things without swapping tips. The L tip is the tip that can max out or nearly max out a 5LPM concentrator and still have downwards adjustability to perform other framebuilding tasks. Note that even a S or XS piloted tip can sometimes max out a 5L concentrator, but the L size flame is more laminar.

M is an in-between size, which can still do it all, however it should really be considered a tip that is hotter than S, but not as hot as L, so you have more time to react making it “safer”, but it isn’t as slow heating as S. Since the L tip can typically max out a 5LPM concentrator, the M tip offers a wider range of flame sizes and more versatility. Rather than being a happy medium in flame characteristics, it’s more about speed versus comfort level for all-purpose type tasks. Most vendors don’t make all 3 sizes of S/M/L. In that case M is the tip larger than S and smaller than XL, or the tip smaller than L and larger than XS. The M tip is larger than S or smaller than L, and may or may not be able to nearly max out a 5 LPM concentrator, although it almost certainly should be able to if piloted.

XS gives superior control for fillets, but tip design plays a role here too. Single orifice tips tend to give a longer pointer flame which are good for precision, but also tend to be blown out more easily, even by its own gas flow/flame when brought too close to the brazement. Piloted tips have a more stable flame, but also a broader flame. The fine control of a precise flame helps when trying to selectively and locally melt a fillet or trying to make filler flow with heat rather than just capillary action or trying to apply heat to one tube near the joint without heating the other tube. I find that the all-purpose tips can lay down a fillet, it’s just harder to control and lay down a nice fillet, especially with propane where you don’t have the extra hot inner cone that gives acetylene precision. Other people don’t seem to need an XS tip to lay down a nice fillet though, so it isn’t strictly necessary. It can also be used for small braze-ons, but so can an all-purpose tip. The XS tip gives a more precise flame than the S tip without giving up too much heat for main joint fillets. With a piloted tip, the main advantage is that you can further reduce the flame size without popping.

XXS is even smaller for smaller fillets, or it can be used for main joint fillets if you like a small flame, but it has worse smoothing action. It gets hot enough for main joints, and it gets hot quickly when turned up, but the heat is very localized so there is little heat smoothing and an increased chance of scorching the flux if you try to heat smooth. It is primarily used for rack fillets, which use smaller tubes, have smaller fillets, and require less heat. You do not need it for racks if you are fine with the natural fillets formed by capillary action (aka tinning), although it will help focus heat if you do use it for tinning. It is for building and shaping rack sized fillets. It can also be used for small braze-ons or building tiny fillets around braze-ons if for some reason you don’t like the fillet formed by capillary action. The XXS tip has a very precise flame and reduced heat output for tiny fillets. This is a very optional tip.

XL is for lugged BB shells and fork crowns that soak up a lot of heat. Using a small tip will just result in hot spots and make it harder to flow filler through sleeves joints because the heat will spread faster than you can apply it except right under the flame. This my result in poor filler penetration and take an excessively long time. A big broad flame will get everything up to temperature more quickly and more evenly. A rosebud (#4) is suggested over a large tip, and you can max out a 5LPM concentrator on even an L tip. Propane rosebuds usually start at #6 but that is too big unless running 10LPM at max output. You really do not need larger than an XL tip, even with a 10LPM concentrator. The XL tip is to get maximum heat from 10LPM, or to get broad even heat (rosebud) from 5LPM. A 10 LPM concentrator is wasted without an XL tip, but with 5LPM, this is a very optional tip.

Individual preferences vary greatly, some may consider a non-rosebud XL their all-purpose tip. You may also find you don’t need smaller tips if you are fast and have good heat control. Recommendations are based around getting an all-purpose size then expanding from there. Small all-purpose has the edge for fillets versus larger tips. Large tips heat things faster which has advantages and disadvantages. Some builders prefer larger, but usually not smaller than this.

You may notice that the tip sizes don’t really line up. For Victor/Gentec that’s because they only have one flame (center hole approx 1 size up). For Paige it’s just because their tips are on the smaller size. Orifice size is given in thou (0.001″) simply because that’s what most have them have been reported in. You don’t need to fill a gap because it’s empty and you may find you don’t end up using intermediate sizes.

If you can only have one tip and don’t know where to start, get a S as an all-purpose tip. If S isn’t available, then something like a M single orifice will work. If buying only a single piloted tip and S is not available, then buy an XS if doing fillet, or M for lugs. Otherwise you can build your set around what you plan on doing.

A focus on fillet frames should get an XS tip which is also suitable for open stay/blade dropouts and braze-ons, but not as suitable for socketed joints. An S tip may also help when it comes to fillet BBs due to the build up of fillets acting as a heat sink or you may find you prefer a S for some or all fillet work. I’m not sure there is a big enough difference to need both with piloted tips. M and L can also lay fillets but I like smaller more precise flames for fillet, making an XS/S combo more ideal.

Socketed/lugged joints should use anything between S-XL depending on preferences and technique. L or XL are good for lugged BBs and fork crowns. S or M will work well for braze-ons, dropouts and side-tacking seat stays without remelting the seat cluster, although L can be used as well. Lugs can be done with any, and my opinion is lug brazing is best done utilizing even heat and not trying to use localized heat to pull filler through the brazement a little at a time. XL is only a small or no gain in heat over L when using 5LPM oxygen, and a L flame has more downwards adjustability than XL so it is more versatile. A S/L or S-piloted/XL-rosebud combo would work well, but if you want a different combo or all or just one due to your own preferences, go for it.

If you want to do fillet, lugs and forks, then a XS/S/L set would work. You may have to tailor this to your preferred vendor of tips and may end up with something like XS/M/XL instead. You can of course, also just buy the full range of tips from XXS-XL from your preferred vendor which will usually end up being 4-5 tips, not 6, due to a gap or two that does not need to be filled. I would also substitute the XL tip for one of the rosebud XL tips, even if it is from a different vendor.

The more I try different tips, the more I find I like a narrow piloted XXS-S for targeted heat, (I can do a fillet with S/M which has the edge for smoothing but like XS/XXS for control), an XL rosebud for broad heat (remember we aren’t trying to get the steel higher temperature with bigger tips, we’re just trying to get it up to temperature faster or more evenly with more heat). I use the all rounder less now, with tool-less changes, it’s a lot easier to change out tips.

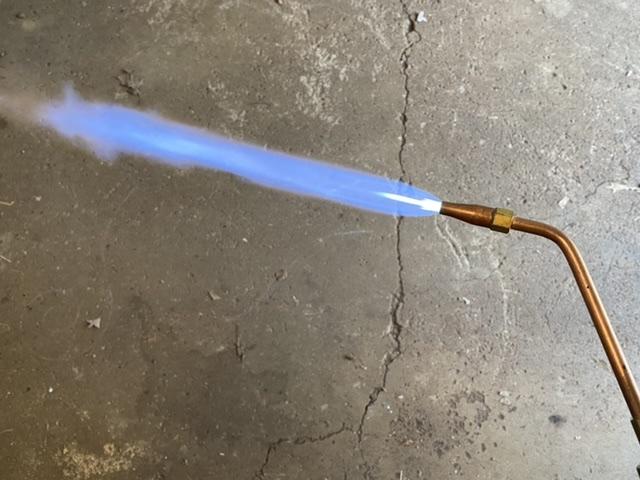

Tip Styles

Tips for acetylene are usually just a plain hole. These can be used with alternative gasses (of which propane is one), but tend to produce unstable flames because the flame speed of these gasses is lower which makes them detach or blow out more easily. When adjusting propane before adding oxygen, you can make the flame jump off the tip and detach when you make the propane velocity faster than the flame speed, so the flame front ends up where there is an equilibrium in the flame speed and propane speed after is leaves the nozzle. This makes the flame intolerant to large adjustments or blow out when there is too much turbulence, wind or you move the flame too fast.

The solution to this is having a low velocity pilot flame on the tip. The low velocity makes the small flames more stable and less likely to detach. These pilot flames will ignite the pre-mix as it leaves the tip rather than the pre-mix relying on the flame speed to push the flame back to the tip. Alternatively you can think of it as having low velocity pre-mix near the tip to keep the flame front at the tip. One tip manufacturer has proposed that it is turbulence around the orifice that causes the problem, which may contribute, but I think the issue is primary of flame speed. These small flames act like a rosebud and add broad imprecise heat, so at least for a XS/XXS tip, should be as small as possible in terms of flame size and in terms of diameter. Piloted tips can take much more pre-mix than non-piloted. Counterbored tips also seem to perform a similar function by creating a shield of low velocity premix around the base, but not as well.

Knurled Pilot

These are preferred over hexagonal pilots. The diameter of the “ring of fire” is typically about 3mm. They can be purchased from Carlisle, IMPGEN, and formerly Meco (unfortunately, Tinman of Tinman Tech passed away), in various threadings but commonly in 1/4-28F. These are make by pressing a knurled insert into the tip, with the ridges of the knurling producing the small jets for the pilot flames. They are typically more expensive at around $30 each but also typically made in the USA. There are also some others made for jewelry torches. Carlisle makes premium versions out of stainless for improved durability. They are all called OX#, but seem to have different sizes. You can see the ring of small pilot flames around the base.

Hexagonal Pilot

Hexagonal pilots are typically found on premium tips that seem to be made in China, but which cost less than the USA made knurled tips. There is very little difference between these and knurled ones but it seems like the knurled ones tend to produce a larger number of shorter pilot flames. The diameter of the “ring of fire” is estimated to be about 3mm, except for the Paige M0, which is too small for framebuilding.

Paige tips are about $20 each and have 1/4″-28 threading, but are not Meco compatible and you must buy an adapter from Paige. Paige has awful, terrible, paranoid customer service and they will accuse people of trying to knock off their tips if ordered without an adapter, and will literally refuse to sell to you if you try to buy tips without an adapter. Many people have had bad experiences dealing with the owner. They used to be Meco compatible, but one day they just decided that they actually aren’t Meco compatible. Their tips are on the small side and the only reason they are recommended if because $20 is more affordable than $30 and they also sell adapters for Smith AT-60 and Victor UN-J mixers which are required if you want off the shelf torch components. If you want to deal with them, don’t talk to them, don’t ask stupid or poignant questions that might set them off (you can basically ask non-technical FAQ questions and might get a sarcastic response saying to read the FAQ), only buy a complete set and order through Etsy.

The Hoke tips are 3/16″-40M(?) threading and only $5-6 but would require custom neck tubes or turning down the threads and brazing them in. There are also some others made for jewelry torches.

Slotted Pilot

Slotted pilot tips are like knurled ones except the slots are cut into the insert instead of knurls and found on tips made in China or Taiwan. It’s not clear why this construction method exists except to reuse machinery used to make cutting torch tips which use similar slotting.

The Welder’s Warehouse (UK) tips are of good quality, and similar to knurled or hexagonal pilot tips. Reportedly they are an odd 1/4″-36 thread and were made in Taiwan, but Welder’s Warehouse no longer answers technical questions and would not confirm the information they told someone else years prior. They’re about $8 each, so very reasonably priced, but have the odd thread and I could not even get information about the thread sizing on the other end of the neck they sell.

The Chinese tips use coarser pilots, ranging from 3-10 in number, and the diameter of the ring for the H01-2 copper clad ones is ~4mm and the one piece ones ~3.5mm. They have M6x1 (H01-2) or M8x1 (H01-6) threads, and necks can be salvaged from H01-2 or H01-6 torches even though the torches themselves are very bad. The construction quality is of course, not great, but they have excellent flame stability and adjustment, but are a bit lacking in precision for the small tips. Even though the pilot openings are large, the pilot flames aren’t. The tips run very hot though, there might be some backfire through the pilots and the counterbore for the face probably absorbs more heat. They’re about $4 shipped for a set of 5, which you might get 2-3 useful sizes out of, so about $2 each. These are fine for medium and large tips, but even a H01-2 #1 tip will easily max out a 5LPM concentrator for an XL or L tip. They’re crude, but provide good performance for everything but fillet tips.

Counterbored/Countersunk

Counterbored tips seem like they’re supposed to produce a similar ring of lower velocity gas around the bottom edge. As seen in the picture, there’s a center cone and a wider cone-like area at the base. These don’t seem to produce quite as stable of a flame as other piloted tips and sometimes not much better than a plain tip. It seems as if these are supposed to work by using flow separation as the bore increases. Or in other words, having a large diameter opening to slow the pre-mix down, but having a narrow high velocity jet in the middle to pierce through the slow part. Lesser flow separations probably why the flame will jump off the tip instead of just gradually increase in distance. I have not had great results trying to counter bore tips and they don’t seem that much more stable than plain tips. I could not reproduce the cone pattern in the picture, but counterbored was easier to adjust and could support a larger flame. I believe the lower stability has to do with the fact that the low velocity gas is caused by the way the pre-mix flows in the air, making it susceptible to turbulence and blowback, whereas piloted tips have independent low velocity ports. The Victor versions are hard to obtain now and the Gentec ones seem to run about $15-20, making them not great values.

Rosebud

A rosebud tip is an array of single orifice holes usually in a circular pattern. This keeps the flame short and broad while having enough velocity at each hole to prevent the flame from receding into the tip. The flame is lower broader than an equivalent single orifice tip, which causes the rosebud flame to wrap around the tubes better and apply heat in a broad area. They do make propane specific ones, usually with counterbores for each hole or a collar at the end, however propane rosebuds typically start at #6, which requires 10LPM of oxygen at a minimum.